The History of Merlo

From 1911 to today

1000

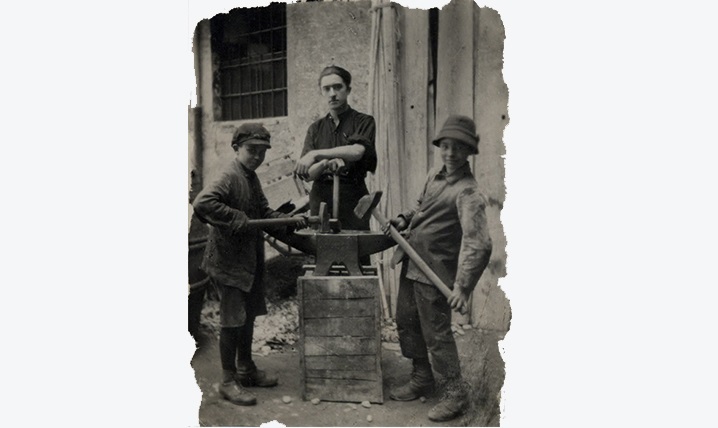

THE FIRST STEP

A WORKSHOP IN THE HEART OF CUNEO

Giuseppe Amilcare Merlo opens a workshop for iron processing. In the small 250 sq.m workshop, which contains a forge, an anvil, two columnar fretsaws and other equipment for iron processing, Giuseppe Merlo begins to diversify his production and starts specialising in precision construction and the production of spare parts for machinery from abroad.

1000

GIUSEPPE'S SONS

HIS CHILDREN GET INVOLVED WITH THE COMPANY’S MANAGEMENT

While Merlo products are becoming more and more popular with customers, Giuseppe’s young children slowly get involved with the company’s management. Natalina, starts helping her father after school and takes care of payroll and administration matters, while Amilcare, after years of being an apprentice, is increasingly present for corporate strategic decisions.

1000

FROM THE CITY TO THE SUBURBS

The rapid growth of the company means that the workshop starts becoming too small. The Merlo family thus inaugurates a new covered 2000 sq.m production area in the outskirts of Cuneo, a few kilometres from the regional capital. The anvil and the forge give way to more innovative machinery such as lathes and bending machines

1000

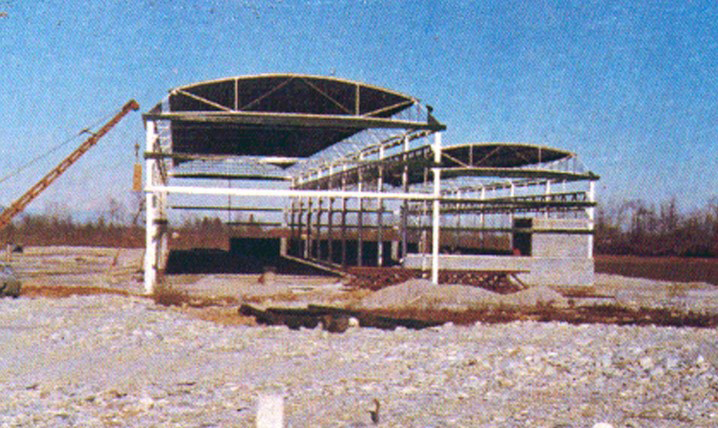

THE MERLO COMPANY IS BORN

The courage, tenacity and entrepreneurial dynamism that has characterised the Merlo family’s artisan activity since its inception are endorsed by Natalina and Amilcare Merlo who, in 1964, establish the “A. Merlo e C. snc di Amilcare and Natalina Merlo” company.

At the same time, construction begins on a new 40000 sq.m plant in San Defendente di Cervasca, near Cuneo: this is the beginning of an exciting phase for great production and commercial expansion.

1000

DM and DBM, the first dumpers and the first off-road concrete mixers

In the modern settlement of Cervasca, the production of dumper trucks and truck mixers for the construction market begins. The first commercial results already confirm the validity of the design and construction choices: the combination of innovation and technology allow Merlo to offer cutting-edge products.

The adoption of an innovative rotating wheel, designed by Merlo, on both models marks the beginning of a long process of research and technological development, which continues today.

1000

1000

1000

SM30, the first telehandler

1981 represents a milestone in the company’s history: the first telehandler, the SM30 model, is introduced. It is an innovative machine, built on an exclusive Merlo project, offering both the performance of the forklift and the versatility of the hydraulic telescopic boom crane.

On the first model there are advanced technical solutions and devices already, rewarded by great sales success (rounded cab with curved windows, telescopic boom side-shift, double hinge for boom articulation, hydrostatic transmission with permanent four-wheel drive).

1000

1000

Panoramic XS, a global revolution

1987 represents a key year for the company’s expansion: the first telehandler in the world is introduced with a side engine and a low-hinged boom at the rear of the chassis. It is the Panoramic XS, the only model to offer total visibility around the vehicle so that work can be carried out in complete safety.

Success is immediate with sales volumes growing constantly, allowing the company to further increase its already high investments in Research & Development, further distinguishing itself from the competition.

1000

ROTO 25.11 XS, the first telehandler with a rotating turret was born

A new confirmation of Merlo’s dynamism and desire to innovate comes with the introduction of the new family of handlers with rotating turrets: the ROTO. It is the first in the world to offer users the possibility to reach every point over 360° without having to reposition the machine.

1000

1000

1000

Turbofarmer, the first specialised handlers for agricultural use

The introduction of the Turbofarmers, a specific range for agricultural use, characterised by as many as 7 models that can all be certified as agricultural tractors, confirms Merlo’s ability to anticipate market needs.

1000

1000

1000

The Multifarmer is born: the telehandler meets the agricultural tractor

With the birth of the Multifarmer, the result of continuous technological research, Merlo’s supremacy in innovation and research is once again confirmed.

The Multifarmer is a revolutionary machine that lifts and transports loads, drives equipment, works the land, pulls trailers and implements, and also carries out the typical operations of agricultural tractors: it’s a unique multi-purpose work system.

1000

1000

CINGO, universal tracked transporters

Merlo is part of a new and promising market, that of transporting materials over short distances, presenting a complete range of machines and attachments for the most diverse handling jobs.

The adoption of exclusive devices immediately enhances the versatility of these compact transporters, and their enormous operational potential commands user attention.

1000

1000

1000

The Merlo Training and Research Centre is born

Built on an area of 50000 square metres of which over 2000 square metres are covered, CFRM is the first centre in Italy for training and instructing machinery drivers and others who work with equipment for handling people, materials, operating machines and agricultural machines.

1000

1000

1000

1000

Eco Power Drive - The innovative EPD transmission system is introduced

To meet the new requirements of economic efficiency and compliance with increasingly stringent anti-pollution standards, Merlo continues research into hydrostatic transmission optimisation, abandoning the traditional management system (called automotive) and adopting a new concept of transmission management, which passes through a hydrostatic system. The new system offers important improvements in the overall productivity of the machine without penalising performance, controllability and ease of use. The goal is achieved through an innovative management system that controls the entire machine, including the diesel engine.

1000

Dynamic Load Control - Merlo CDC system, a true revolution in the concept of safety on frontal telescopic handlers.

With the new advanced Merlo CDC (Dynamic Load Control) system, Merlo makes another leap in the field of safety. Merlo technicians created an automatic system for managing the machine’s stability parameters, which allows the telescopic handlers to perform at their very best. Striving for excellence, the Merlo CDC (Dynamic Load Control) system was also developed with the aim of making the best use of the requirements prescribed by the recent EN 15000 standard on the longitudinal stability of telescopic handlers.

1000

1000

1000

CENTENARY COMPANY - Merlo Spa is registered as a historic company

After a thorough analysis of documents and registration deeds, the Centre for Business Culture and Unioncamere certify that the Merlo family’s business activity began back in 1911. Merlo thus enters the exclusive circle of “centenary” companies that have forged the history of Italy and the Cuneo province. The official award ceremony takes place on 5 October 2014 in the Hall of Honour at the Cuneo Chamber of Commerce.

1000

1000

1000

INTERMAT 2018 TRADE FAIR - New Construction range unveiled

Merlo presents at Intermat 2018 in Paris the new, completely renewed range of telehandlers for the Construction sector. 15 new models are introduced at the fair. Thus begins the production of new models that adopt constructive solutions and exclusive technologies.

1000

INDUSTRIAL EVOLUTION - Five years of industrial investments

Continuing its industrial evolution, in 2019 Merlo continues the 2015-2020 investment plan with more than 140 million euros already invested. An ambitious five-year project, in terms of structural investments, which goes on to change the production concept, developing new ranges of products that are increasingly in line with market demands. The use of automated and intelligent systems has an important impact on business and production processes.